Implementing Digital Farming’s Five Major Needs

Building a house starts with a plan and then a foundation; it does not start with doors and windows. From foundation the house progresses to walls and roof, and then the doors and windows. Building any system starts with a plan, a vision of the future, and progresses in an orderly way by building a foundation, assembling the walls and roof, and then adding the major infrastructure and trim. Too often, system development is started with the walls and roof, sometimes even major infrastructure; all of this in the absence of a plan and foundation.

In a less distant past, a study was completed that showed, approximately, that the first five percent (5%) spent on architecting and engineering the system, up front, locked-in 60% of the future total system cost. This means it is critically important to get the architecture right, up-front, before anything is fixed in design.

That future form, the architecture of the system represents what the system needs to be. Every piece of the form integrates and interoperates; and every milestone is clearly specified within that form. Visioning the future form is based upon ‘what’ needs to be done and is the origin of the engineerable specification. “How” it is to be done is significantly easier if “What” is well specified. “How” is what everyone is comfortable with; “What” is often skipped with a resulting lack of a foundation.

From this vision of the “need”, it is possible to look back from this future and establish the milestones that would be along that developmental path. This is true for product definition/ development/ deployment, and a host of other tasks. Planning is now about more agile smaller steps; how to get from milestone 1 to milestone 2, and beyond, versus how to get from milestone 1 to milestone 5. It clearly ensures the required efforts lead to where the system needs to go. This is not a solutions exercise but an operational exercise that requires the synthesis of a lot of external inputs. It requires an additive, what the system is, and subtractive, what the system is not, approach to craft, mold, and shape the future.

MORE BY MICHAEL R. COLLINS

Digital Farming has an overall operational description that is spelled out in a previous article. Like the house, the development of this system builds from a plan and foundation, and it progresses in an orderly way to the equivalent of the final trim. For digital farming this development occurs in five major milestones or architectural solution forms in an order of precedence. These five major steps are Communications, Digital Ecosystem/ Platform, Digital Twin, Industrial Internet of Things/ Sensors, and, finally, analytics and algorithms. These represent the foundation and the intermediate states of walls/ doors/ etc. Together, they represent an integrated whole. Holistically defined and rigorously specified, they enable distribution of processes, federation of data, open innovation, and incremental, limited functionality, agile management; ultimately, the deployment of what is needed.

Communications

The farming or cultivation ecosystem represents a physical environment that is remote/ isolated, austere, and even hostile to technology. The nature of this environment is such that it involves long distances, temperature and weather extremes, and relatively long cultivation cycles. The digital approach includes gathering, transmitting and analyzing this massive quantity of data. Data communications is foundational.

Electrical power is equally foundational and needs to be sufficient for sensors, actuators/ controllers, and communications. It must be available for at least the length of the cultivation cycle. This means that sensors, actuators, and communications must be architected to manage the least amount of power.

Finally, generating decision quality information must be done inside the decision loop being examined. This means it must be sensed, gathered, transmitted, and analyzed in real-time. Real-time information impacts the processing, storage, sensing, analytics, and presentation of decision results. The urgency of this milestone cannot be engineered later; it must be addressed holistically, up-front.

Digital Ecosystem/ Platform

Before the system that models the cultivation can be implemented, there must be a digital platform that can provide security, access, sequencing, system management, business metrics, etc. It must be able to orchestrate the administrative imperatives, be semi-autonomous across a wide geographic area, have a limited requirement for human intervention, and be transparent to the user.

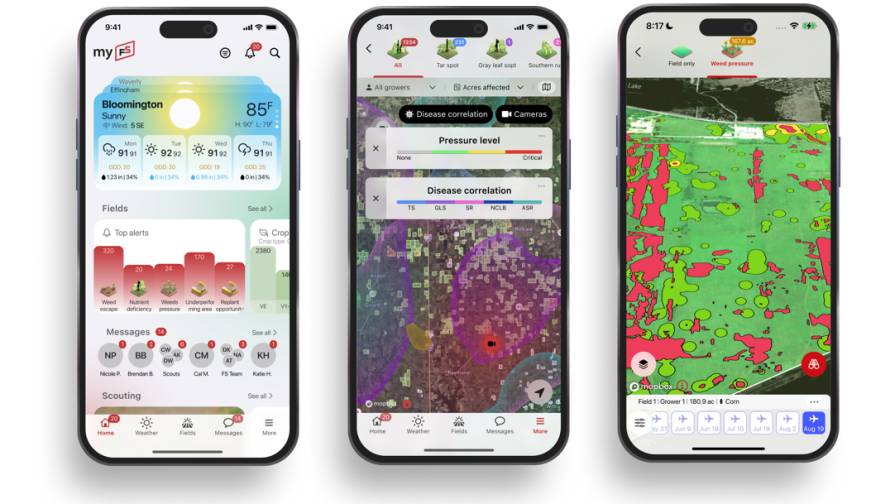

Further, because of the nature of this concept, this platform must be able to reach outside of its domain into the agricultural ecosystem of stakeholders, data sources, and agronomic information. It needs to access disparate information from outside sources like weather, market forecasts, farm management applications, and others. This ecosystem is required so that any decision information can be securely provided to those stakeholders within the context of the immediate decision loop or current cultivation event.

The foundational services for each of these administrative imperatives are embedded in the platform and must be additive, agile services to maintain the system functionality. This ecosystem/ platform can be released with minimum initial functionality, and this milestone requires a design able to initiate, refine, and extend the capabilities of the system into the future. It is critical to embed system utilization and management metrics services and provide stakeholder reports of these on an ad hoc, real time basis.

Digital Twin

The essence of digital farming is the digital twin. The digital twin is the predictive production environment. It supports many users running many threads of inquiry. This digital twin milestone is the step that collects, stores, processes, and analyzes the sensed and non-sense information in the decision loops of the cultivation. It includes all aspects of the cultivation including seed selection, soil management, stress determinations, and mitigation and harvesting. It extends into the farm management system to provide revenue and cost information. This model truly represents a digital twin of the farm and the current cultivation.

This model, unlike its real world equivalent, can be run many, many times to examine alternatives. It can be used to predict outcomes using data from previous outcomes and predictive results. At scale its utilization has minimal marginal cost, and its results can illuminate significant marginal revenue, limited production costs, and incremental profits.

This digital twin runs on the digital platform and is a part of the digital ecosystem. It accesses farm and network information through the communications networks already established, and it interoperates at the functional interfaces to support end to end system interoperability. Like the ecosystem/ platform the digital twin must support new algorithms/ analytics and enable on-line real time, agile upgrades at the microservice, service, and application layer.

Industrial Internet of Things/ Sensors

This milestone is where the rubber of digital farming literally hits the road. Without the digital instruments that sense and take actions, the digital farm is just a concept. But, without the preceding, this Industrial Internet of Things (IIoT) is not scaleable or sustainable, and it is fraught with quality and repeatability issues. This is a next milestone in the development and deployment of a Digital Farming system. It is the infrastructure of the house; the wires and plumbing.

Each decision loop, as addressed in the previous article on imagery, will require that the sensor be tied to the decision loop and objective. Resolution, frequency, environmental factor being sensed, etc. are all developed and deployed based upon the required action of the OODA loop and the communications, platform, and digital twin. The IIoT merely becomes “plug and play” additions.

Analytics and Algorithms

This last and final milestone is the continuous process of examining the data collected in the previous deployment milestone. This milestone may include many analytic processes or algorithms depending upon the data, its context, and the decision information being developed. In general, these processes and algorithms should be automated such that the user is not required to lean on prior or specialized knowledge. The need for this milestone to be highly automated does not remove the requirement for the system design to embrace this specialized knowledge. This requirement makes the implementation complex.

Over time as more and more insight is gained about the field, crop, or process this milestone may become more complex and/or require additional reporting. The platform and twin should support agile analytic and algorithmic upgrades across the system as previously noted in the earlier milestones. This milestone is the final milestone in the initial deployment of the Digital Farming system.

Summary

The nature of this concept is that it will continue to evolve, and it will become a daily work environment for many stakeholders. This system will change the risk profiles of all of the users, and as the stakeholder community gains trust, newer financial products will be developed putting more demands upon the system to be even more flexible and extensible.

The precedence and rigor of the stated approach will minimize the change environment and support an agile approach to the system and the organization. Because of the operational nature of this deployment, maintenance, sustainment, management, and governance will be continuous. Because of the step wise development and deployment and the early and rigorous definition of the architecture, the 60% commitment of total life cycle cost will be contained, and the costs of maintaining an operational deployment will be minimized. Finally, if no resources are put back into the system, it will gain entropy and die, but this layering of capabilities will minimize these on-going resource needs.